Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

What is a Peristaltic Pump?

I believe most users are not very familiar with this type of pump. Peristaltic pump, also known as the hose pump, is a new type of industrial pump, it is the product of modern industrial development, widely used in pharmaceutical, food, chemical and other industries, transport with some sensitive, viscous, corrosive, grinding, high purity requirements, and containing a certain granular material medium.

Structural composition

The peristaltic pump consists of three parts: the driver, the Pump head and the hose. The fluid is isolated in the pump tube, the pump tube can be replaced quickly, the fluid can be retrograde, can dry run, low maintenance costs, and other characteristics constitute the main competitive advantages of peristaltic pump.

Working principle

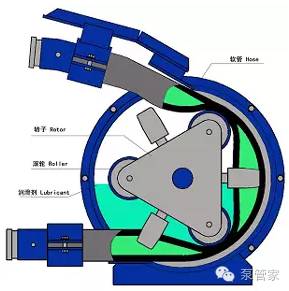

The peristaltic pump is mainly composed of a drive, a hose, a roller 2 installed on the rotor 3 and a shell. Among these members, the hose 1 is made of elastic material such as rubber or plastic, and the rest are metal rigid parts. The movement of peristaltic pump is gentle, suitable for shear resistant fluids. The simple and reliable structure of this pump is also the ideal choice for pumping medium flow, medium pressure wear, fragile and corrosive fluids. They are also simple to maintain as only the hose is in contact with the fluid.

The peristaltic pump works by taking advantage of the ability of a soft elastic tube to withstand deformation and return to its original shape. A peristaltic pump is like squeezing a fluid filled hose with a finger clamp. The fluid moves forward as the finger slides forward. A peristaltic pump works the same way except instead of a finger, it has a roller. Fluid is pumped by alternately squeezing and releasing the pump's elastic delivery hose. It is like squeezing a hose between two fingers. With the movement of the fingers, a negative pressure is formed in the pipe and the liquid flows with it.

Peristaltic pump is a section of pump tube between two rollers to form a "pillow" shape of fluid. The volume of the "pillow" depends on the inside diameter of the pump pipe and the geometry of the rotor. The flow rate depends on the product of three parameters: the speed of the pump head and the size of the "pillow" and the number of "pillows" produced by each turn of the rotor. The size of the "pillow" is generally constant (except when pumping particularly viscous fluids).

Compared with the pump with the same rotor diameter, the pump with the larger "pillow" volume has a larger fluid volume transported by the rotor per revolution, but the pulsation degree is also larger. This is similar to the case of membrane valves. The pump that produces the smaller "pillow" volume, the fluid volume transported by the rotor is also smaller each turn; Moreover, the rapid and continuous formation of small "pillows" makes the flow of fluid more stable. This is similar to the way gear pumps work.

classification

The use of peristaltic pump is in order to get the required flow, so according to the operation and use of peristaltic pump, divided into:

1. Speed regulating peristaltic pump:

With the basic control function of peristaltic pump, display speed, start and stop, direction, speed adjustment, fill empty, power off memory, external control input and other functions.

2. Flow type peristaltic pump:

In addition to the basic functions, increased traffic display, traffic correction, communication and other functions.

3. Distributed peristaltic pump:

In addition to the basic control functions, it has added flow display, flow correction, communication, liquid distribution, suction, output control and other functions.

4, custom (OEM) peristaltic pump:

With a series of different flow range of Peristaltic pump head, customers can according to their own equipment needs, design different peristaltic pump driving circuit supporting use.

advantage

Can handle gas-bearing fluid; Low shear force, can transport shear sensitive, oxidation corrosion sensitive fluid, suspension, wear resistance is strong; The diameter of solids contained in the fluid is allowed to reach 40% of the inner diameter of the tube component; There is only one contact component and no sealing is required. Fluid only contact the pump pipe, and do not contact with any other parts; High precision; Self-priming; Can be idled; With two-way equivalent flow transmission capacity; No liquid empty operation will not cause damage to any parts of the pump; Can produce up to 98% vacuum degree; Only the hose needs to be replaced, and the replacement operation is very simple.

shortcomings

With flexible pipe, the pressure will be limited, conveying pipe failure will cause product loss; Pump speed is low and vibration is large. The traffic range is narrow.

Care and maintenance

The maintenance of peristaltic pump is very simple, which is one of its main features!

1. The roller shall be oiled regularly to keep the roller in a good lubrication state. Note: the tightness of the roller should be checked when filling oil. If it is found that the roller is too loose, tighten it with tip pliers. If it is found that the roller has a sense of loosening and cannot be eliminated after adjusting the tightness, then the wear condition of the inner bearing of the roller should be tested twice, and it can be removed to replace the bearing or the roller.

2. The roller bearing should be greased every six months or so.

3. After running for a period of time, the new reducer will drain the oil in the tank and add 30# oil again.

We only know that peristaltic pumps have low maintenance costs, but we don't know where. Only those who have used peristaltic pumps will know how much they have saved in using costs.

Other pump classes for transmission media maintenance and repair time needs five or six hours, here is not to say what kind of pump class, I believe that used friends understand. The peristaltic pump only needs to replace the pump tube to complete the maintenance work.

It also needs to be moved, transferred and reinstalled during maintenance, which takes up additional time. This has a great impact on our work efficiency. In this way, you can think of how convenient the replacement of the pump pipe is. And we can transfer the liquid, choose different prices of the pump pipe.

Does the peristaltic pump need cleaning? Does it require maintenance? Peristaltic pump is not needed to clean, because in the transmission process of the liquid will be in contact with the peristaltic pump pump machine, just through the pump tube for transmission.

The maintenance cycle of the peristaltic pump body is also very long. If the condition of the pump is better, it only needs half a year to carry out maintenance on it.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.